Image by: Andrew Shipley

Secondary treatment is a biological treatment process that removes contaminates such as BOD and nitrogen in the forms of ammonia, nitrite, and nitrate. It also removes total suspended solids through a clarifier.

Currently SPA 1 has three operational plants, each with a pair of oxidation ditches and a secondary clarifier. The oxidation ditches are operated under Krueger’s proprietary BioDenitro mode. This mode accomplishes aerobic nitrification (conversion of ammonia to nitrate) and anaerobic denitrification (conversion of nitrate to nitrogen gas) in four phases. The team determined that a key weakness was the time it takes to transition between phases and tried to eliminate it in a final design of Plants 4 and 5.

Image by: WCWW

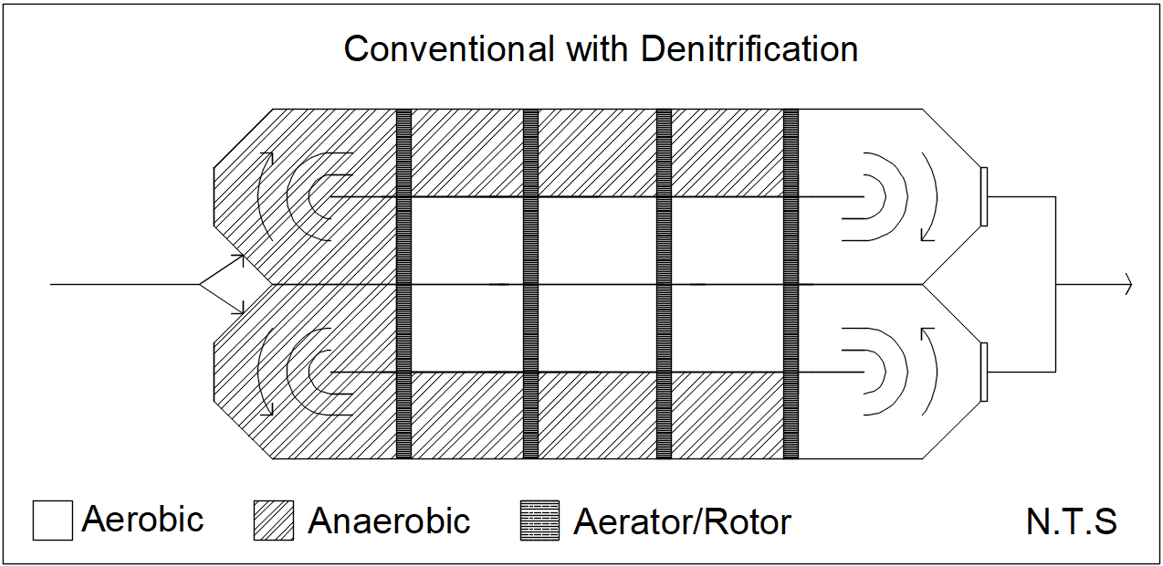

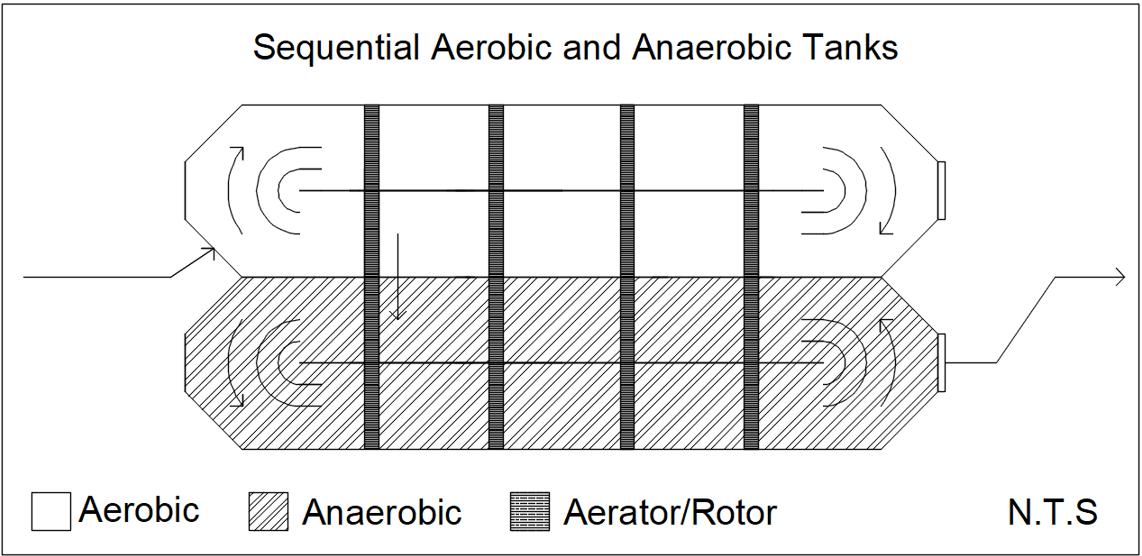

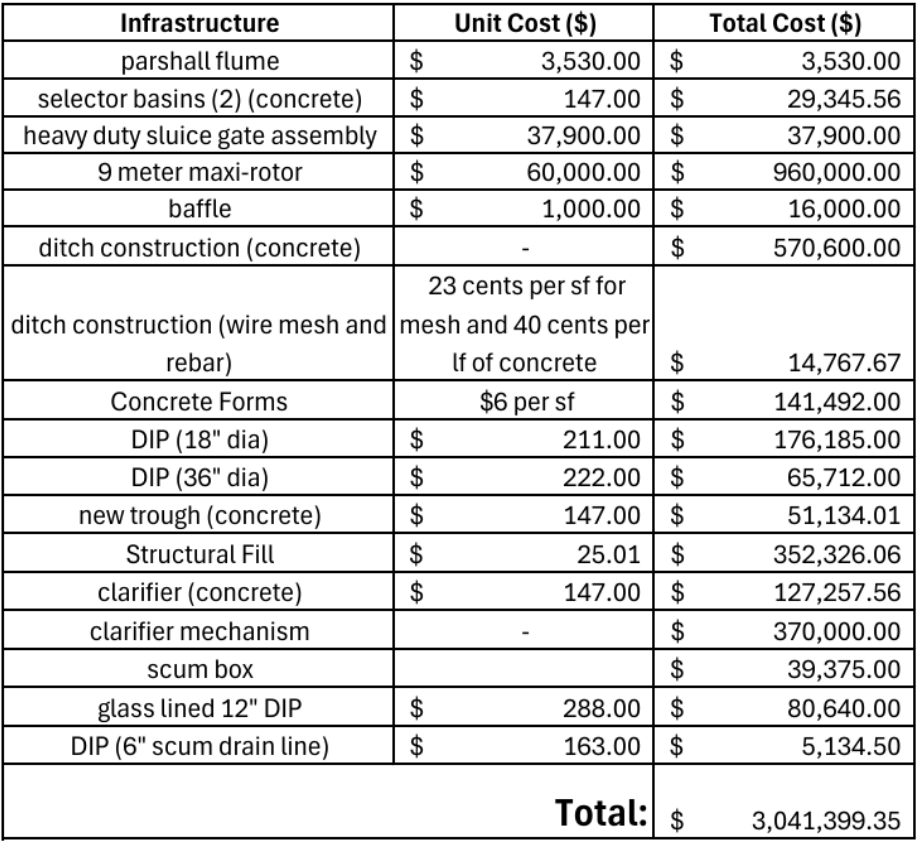

T Three alternatives were developed for secondary as required by the Arizona Water Association Student Design Competition. Two of these were required to adapt Plants 4 and 5 without changing their footprint. The third was the addition of a Plant 6. Alternative 1 was a conventional oxidation style where each plant was divided into two tanks, and each tanks were further divided into aerobic and anaerobic zones to achieve nitrification and denitrification. Alternative 2 was sequential aerobic and anaerobic tanks. This alternative would require the addition of a BOD feedstock such as methanol to ensure there was enough BOD for denitrification, but this would allow for further nitrogen removal. Finally, alternative 3 was a Plant 6 that would be identical to Plants 4 and 5.

Images by: WCWW

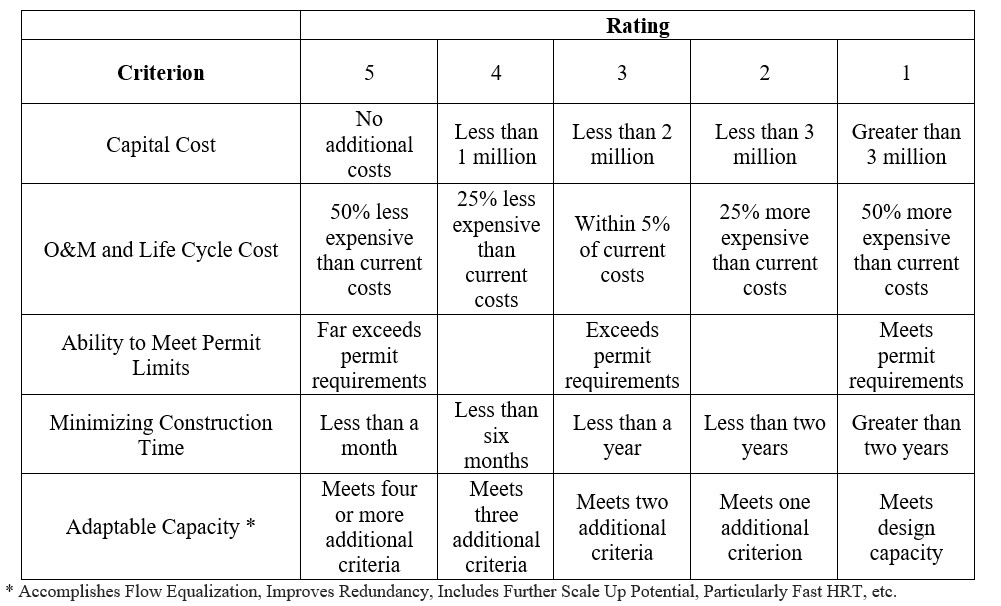

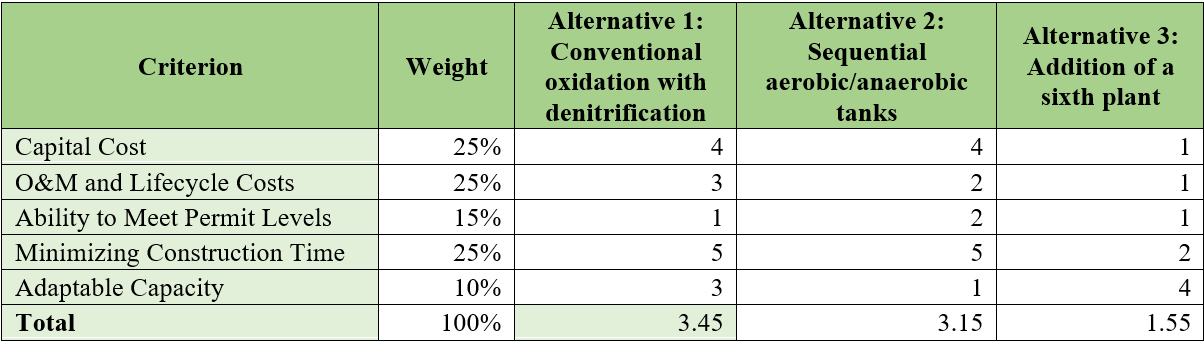

Each alternative was scored 1-5 (1 being the worst and 5 being the best) based on how well they met each criterion. A summary of how each criteria was scored can be found in the following table.

The alternatives were evaluated using a weighted decision matrix. Five criteria were used. Four of these were required by the competition (capital costs, O&M/lifecycle costs, ability to meet permit limits, and minimizing construction time), the team also adaptable capacity which was a measure of how an alternative either improved redundancy or prepared the facility for further expansion.

Using the decision matrix, it was determined that alternative 1 was the best alternative. This was largely due to how it had limited capital costs, minimal increases to O&M, as well as improved facility redundancy. This alternative was then further developed to determine the required return and waste activated sludge flow rates, as well as the aeration scheme.