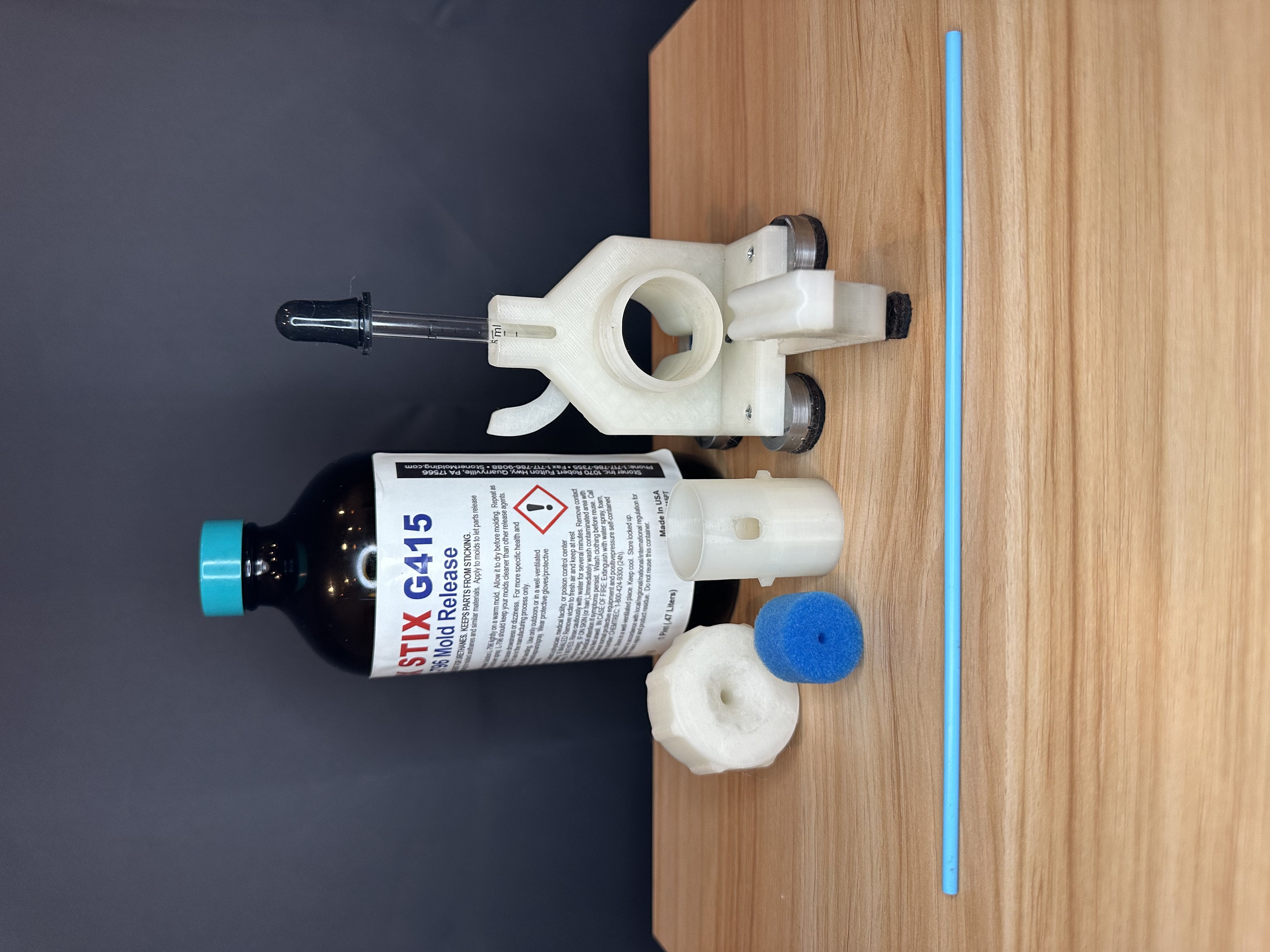

Mold Release Dispenser

Our task is to develop an automated mold release application system to enhance the efficiency, and precision of catheter manufacturing. Our aim is to create a device that is consistent, adaptable, and user-friendly solution to meet the current demands of modern catheter manufacturing.