Project Description

Project Overview

Northern Arizona University Engineering Department in Cooperation with The Boeing Company Capstone Design Project.

Client Profile

The Boeing Company (Light Structures Fabrication and Assembly)

- Primary Contact - Marvin Dansie - Chaku-Chaku Line

- Secondary Contact - Ralph VanHee - Chaku-Chaku Manager

Schedule

This is a two semester project that will span August 2000 to May 2001

Please see our calendar section for more project milestones.

- Research

- Status report 1

- Status report 2

- Status report 3

- Final Report

Project Location

Northern Arizona University is locatied in Flagstaff Arizona

This project is very machining intestive and most design and construction will occur in the engineering facility.

Abstract

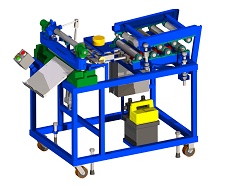

This report details a new design for a specialized "Chaku-Chaku" prototype sponsored and to be used by The Boeing Company. The machine will be integrated into a single part flow manufacturing line at the Light Structure Fabrication and Assembly division in Auburn, WA. This Machine will enable Boeing to manufacture blanks that were previously purchased from an outside vendor. Not only can the company produce the standard 4" x 6" blank, they will also be able to cut a variety of sizes. This will all be accomplished in one compact "Chaku-Chaku" machine.

Introduction

The Boeing Company utilizes a process termed "Chaku-Chaku", which means, "load-load" in their manufacturing process of small air frame parts. This term refers to the single part flow process when the operator proceeds from machine to machine, taking a part from the previous operation and loading it in the next machine until the final part to be handled is the finished component. The "Chaku-Chaku" single part process increases the amount of completed parts in an allotted time. Each Chaku-Chaku line is comprised of approximately 5 relatively small machines, all run by one operator.

Until this time, Boeing has out-sourced its aluminum blanking. The Boeing Company uses a standard 4" x 6" blank for all their light structure Chaku-Chaku machines. This leads to excess of material after the parts are punched from the blank. From the visit in October, the team noticed an approximate 80% waste in material for a certain geometry that was being produced. The production of the parts has, up until now has been a source of inefficiency and material waste.

The Boeing Company has asked a team of Northern Arizona University students to create a Chaku-Chaku that would cut aluminum in to lengths specified by the user. The machine would then be integrated into the current Chaku-Chaku lines in the Light Structures Fabrication and Assembly plant in Auburn, WA.

Scope of Work

The Boeing Company has asked for a finished prototype that meets or exceeds their specifications. In addition to the finished prototype, they have requested an itemized budget, design drawings/decisions, detailed drawings, appropriate mathematical analysis, project schedule, detailed budget, maintenance and calibration.

Machine Requirements and Specifications

The Boeing Company provided a list of requirements and specifications to be taken into consideration when designing and building the blank shear machine.

The requirements includes:

- Aluminum will be delivered to the machine from a coil or from 4' strips.

- The machine will be powered by 120VAC 15A and/or 80psi shop air.

- There will be no marring on the blank's surface.

- The machine will deliver one blank within 30 seconds.

- The machine must be portable.

- The machine shall have the dimensions: 4ft high by 4ft deep by 2ft wide.

- The machine will straighten raw material from a coil, before being processed.

The blanks also have a list of specifications as follows:

The blanks also have a list of specifications as follows:

- Material thickness 0.028" - 0.100"

- Material width 2" - 12"

- Material length 2" - 12" / 0.125" increments 0.03" tolerance

- Edge Chamfer 0.0625"

- Edge Burr 0.01" max

- Blank Bending 0.1" max

Design Philosophy

An aggressive design philosophy is necessary in order to produce a satisfactory design. An underlying blueprint of the design for the blank coil shear machine was devised to guide in the decision making process.

The design philosophy includes:

- The machine will be designed for the functionality, reliability and quality of the prototype.

- The machine will be simple to use.

- The machine will be safe.

- The machine will minimize time and effort to load, adjust and operate.

- Minimal maintenance will be needed on the machine.

- The prototype will function reliably throughout machine life.

Design decisions

When considering possible designs, an ample amount of research was conducted. The research was divided into the separate systems in the shear Chaku-Chaku. These were blank cutting, coil straightening, and automation.

For blank cutting, it was necessary to research an angled guillotine knife, a flat knife, pneumatic nibblers, a band saw, a laser knife, a water knife, and a slitter knife. In order to evaluate what was the best option to cut the blank, it was necessary to consider price, the amount of force needed, the plausibility of integration into the machine and the ease of use of the particular device. The flat knife would require a great amount of force to cut the material. Nibblers would make a very jagged edge on the blank. A band saw would be too difficult to integrate into the machine. Laser and water knives were too expensive and impractical. The slitter knife would have been difficult to use. Therefore it was concluded that the angled guillotine knife would best suite the needs of the project because the force to cut a piece would be greatly reduced, and the knife would be easy to integrate into our compact machine.

The next sub-system to be evaluated was the coil straightener. The team researched various sheet metal straightening devices. Some options that we considered were reverse rolling, pressing and tensioning. The team concluded that both pressing and tensioning would have a tendency to mar the blank and perhaps undesirably alter the material properties. In addition, both of these options would unnecessarily complicate the design. Reverse rolling is most often used for straightening wire and was found to be the best alternative for the need of the project. Reverse rolling is commonly used in many applications, and integrated well into our design.

The next area of research was how to automate the indexing system. The material, as per the requirements, would be cut in some increment of 1/8". Viable indexing options that were researched were: optical sensors, adjustable stops, edge locators, stepper motors, and rotary sensors. An optical sensor was the best choice. In consideration for the electronics the optical sensor was the easiest to integrate, and was therefore the best choice.

With the major design decisions in place, there was a struggle to decide between building a shear and purchasing one. Research indicated a hand operated shear closely fit our design requirements. A similar hand shear in the machine shop showed promising results before the decision was made to purchase our own shear. Since the test was successful, the Di-Acro hand shear was purchased and incorporated into the machine design. This meant obtaining permission from the "Chaku-Chaku" group to exceed the specified width since the purchased shear exceeded the requirements by approximately 8".

Conclusion

The working prototype of the Chaku-Chaku shear machine has met the specifications provided by The Boeing Company with a notable exception of external dimensions. The prototype performs up to the design specification. In searching for a shear to closely meet our requirements, we located a 12" Di-Acro shear. This 12" hand shear would have been a better fit into our design however, the new cost of this shear would have used our entire budget. In further research we found a 24" used Di-Acro shear that fit well within the budget and was identical to the 12" shear except for the width. The 24" used shear required minimal modification and setup. This shear will provide Boeing a long life of operation. Replacement parts can be purchased directly from Di-Acro (See reference section).

The one feature that we were unable to fully test is the straightening system. There is evidence that the straightening rollers can indeed yield material, however the team was unable to feed aluminum from a coil into the machine.

Overall, the team feels that this project was highly successful. It is not very often that a prototype works correctly the first time, but this prototype performed exceptional without any major modification. We feel grateful for the opportunity to have participated in this exciting project for The Boeing Company. Please see Appendix A for further redesign considerations and Appendix E for a detailed project budget.

Project Special Thanks

- Dick Radcliff - Hydraulics Expert

- Greg Thomas - owner: The Thomas Co.

- Ron Boyer - Boyer Metal

- Dave Noack - East Flagstaff

- Brian Burt - Mesa Machinery Sales

- George Bain - W.L. Gore

- Dave Myers - W.L Gore

- Dave Hartman - Project Supervisor, technical advisor

- Don McCallum - Shop foreman, technical advisor

- Justin Myers - Shop tech, technical advisor

We would like to extend our greatest thanks to a few people that took time out of their busy live to help us. This project would not have been a success without their input.

References

Chaku-Chaku Research

Guillotine Knife research

New/Used Machinery

- Company where used Di-Acro was purchased

ACC Machinery Company Inc, 747 Grand Ave, Phoenix, AZ 85007 (602) 258-7330

- Brian Burt company president was helpful in discovering new resources. Mesa Machinery Sales, Inc

128 W. Boxelder Pl.

Suite 117

Chandler, AZ 85225

(480) 545-0275

(800) 542-8559

http://www.mesamachinery.com

Text Reference

- Shigley, Joseph Edward. Mechanical Engineering Design 5th Edition, 1989 McGraw-Hill, Inc

Notes

This page was summarized from the Design Document submitted to our client. To view this document, open the PDF shown below. Unfortunately, due to space the PDF does not include the appendices of the document.

Due to this documents large size, it may take a few mintues to open over a modem connection.

Final Boeing Report (PDF format)