Table of Contents

Problem Overview............................................................................................................... Page

2

Requirements and Specifications..................................................................................... Page

3

Mechanical............................................................................................................... Page

3

Electrical.................................................................................................................. Page

4

Environment............................................................................................................. Page

4

Documentation........................................................................................................ Page

5

Testing...................................................................................................................... Page

5

General..................................................................................................................... Page

6

Design Philosophy and Approach.................................................................................... Page

6

Deliverables and Schedule................................................................................................ Page

8

Design Section................................................................................................................. Page

10

Design

Summary.................................................................................................. Page

10

Digital

Design........................................................................................... Page

11

Schematics,

Diagrams, and Drawings.............................................................. Page

11

Analysis

and Simulation....................................................................................... Page

12

Tradeoff

and Design Decisions.......................................................................... Page

12

Parts

Description.................................................................................................. Page

13

Budget Section................................................................................................................. Page

14

Acceptance Document..................................................................................................... Page

16

Appendix A - Schematics and Simulations.................................................................. Page

A-0

Appendix B - Parts Information and Research............................................................ Page

B-0

Problem Overview

The device we are designing is a universal strain gauge amplifier. The strain gauge is simply a transducer and, therefore, will be simulated by feeding an analog signal as the input to the system. The resistance of a strain gauge changes as the surface it is mounted to experiences mechanical strain. Typically they are made from Silicon and used as force sensors. Since the signals from strain gauges are highly varied, our amplifier must have the capability of downloading configuration data to the amplifier in order to ensure that zero and span controls are not needed. The range of signals produced by the strain gauge can be simulated for this prototype unit.

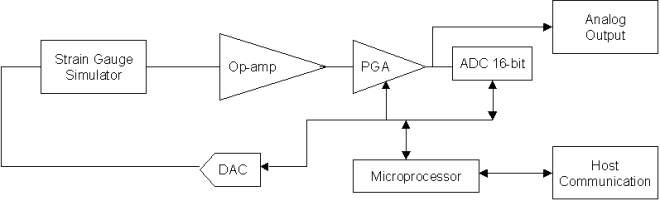

The circuitry of the system consists of some op-amps,

a programmable gain amplifier (PGA), a 12-bit analog to digital converter

(ADC), and a digital to analog converter (DAC). A block diagram of this system is included in Figure 1.1

below.

The resistors simulate the strain gauge and provide a

range of signals to be fed into the system.

The op amp is then used to remove the DC offset into the system. By simulating the characteristics of a

strain gauge we are able to test the amplifier circuit without an actual strain

gauge device. After receiving the

signal from the strain gauge, the PGA sets the gain of the amplifier to x1, x2,

x4, or x8. The signal is then sent to

an ADC, which in turn feeds the converted data back to the microcontroller for

further analysis. The microcontroller

receives, through a serial communication port, the data for the gain stage, the

ADC, and the DAC. It sets the gain of

the PGA, calibrates the system via the DAC in the control loop, and tells the

ADC whether a digital or analog signal is required.

The focus of this project is to prototype the

amplifier system. The final product

would be customized by Dataforth to fit specific applications, due to the

variety of uses of strain gauges in industry.

Some examples in industrial processes that could utilize this amplifier

are steel processing, automobile manufacturing, airplane testing, etc.

Figure

1.1, System Diagram of Strain Gauge Amplifier.

Requirements and Specifications

Mechanical

This section describes the physical characteristics

of the entire system. The [DRY1]amplifier is, at this time, primarily a prototype; as

a result the mechanical aspects are not limited in size and weight. However, the entire circuit will be

constrained to the following dimensions, which will allow for greater

flexibility in both the manufacturing and design of the product.

- Size will be kept within

2ft width, 2ft length, and 2ft height.

- Weight will be

less than 20 pounds.

- The components will be

centralized fully on Vectorbord.

- The

interconnectivity of the components will be with wires and solder.

Electrical

This section contains the specifications for the electronic components and electrical interfacing of the system. It provides detailed characteristics of the individual components, as well as the general requirements for their interfacing.

·

Bandwidth is not

critical. However, it will be limited

to a maximum of 100Hz.

·

The PGA will have

preset gains of 1, 2, 4, and 8.

·

The resistors should be

rated at 1/4 watt and have a tolerance of 1 or 2%.

·

The bridge is powered

with a laboratory supply, adjustable from 1 volt to 10 volts.

·

The Microchip PIC

family PIC17C756 microcontroller will be used.

·

The microcontroller

communicates through a serial port with the computer and receives commands from

the host computer and sends data back in response.

·

The microcontroller

sets the gain of the PGA and loads the data into the DAC from the computer.

·

The DAC (D/A) provides

the analog signal to zero the bridge.

·

The data will be

displayed on the screen of the computer (PC).

Environment

This

section provides specifications on the environment that the system will operate

in. Since environment conditions will

vary greatly, depending on the use, these specifications must encompass a wide

range of possible scenarios.

- Must be able to

operate in environments of 0C to +55C.

- The system should

work under normal atmospheric conditions, with no vibration or shock to

the system.

Documentation

This

section provides a description of the documentation needed to properly operate

the system, as well as the functionality.

- A user’s guide for the

amplifier will be made available after the testing has been completed.

Testing

This

section discusses the processes for which testing will be implemented. It describes the conditions for which the

amplifier must satisfy.

- Simulation of strain

gauges through the use a four-resistor bridge of 3 100-ohm (±2%) resistors and a single resistance adjustable

from approximately 95 ohms to 105 ohms.

- Verify that the computer

sends commands to our system and receives back data through the serial

ports.

- Verify that the

microcontroller will calibrate the system.

- To check the accuracy of

the system, measure the input voltage with a digital voltmeter and compare

to the output.

General

This section provides general

requirements that the system must comply with.

The device will be used in various situations, each of which will

require its own unique set of specifications.

In order to accommodate this flexibility, the device will be designed to

allow the user to easily change the configuration of the device with minimal

problems.

- The system must not

need zero and span controls.

- The accuracy of the

system must be at least 0.1%.

- A simple control loop

should calibrate the system.

Design Philosophy and Approach

Our project has been broken down into different

modules. These modules are assigned to different team members. The team leader

is responsible for the system integration and is, therefore, involved with all

the individual modules assigned. The

modules are as follows:

-

Interfacing between

controller and system (I/O Bus)

-

Web page development

-

Documentation

-

Microcontroller coding

and implementation

-

DAC and ADC interfacing

and accuracy

-

PGA interfacing and

functions

-

Strain gauge simulator

-

System integration

We have broken down our project into different

categories assigning specific tasks to individual team members. The reason for this division of labor is to allow the individual to become highly

specialized in each area of interest to our project. This in turn implies that each individual on the team will play a

vital role in the outcome of the project due to the fact that final design is

an integration of each other’s contributions.

This also means that each member must perform in order to achieve

success.

In order to insure individual success, the team

leader will observe and obtain feedback from the individual members throughout

the process. Due to the knowledge of

the individual projects, it will also be the duty of the team leader to

supervise the final integration of the product after the completion of the individual

stages. Below is a breakdown of the

different applications the team members will take responsibility for.

This

listing is by no means limited to or exclusively for the individual assigned to

the task, but rather a responsibility for which they are accountable.

Our philosophy is to develop, on schedule, a

functioning, reliable system (microcontroller controlled strain gauge

amplifier) with accuracy that meets or exceeds specifications.

Deliverables

Project Proposal Dec. 13

Bill of Materials Dec. 13

Start Coding Jan. 25

Start Testing Feb. 10

System Integration Mar. 10

Final Testing Mar. 10

Complete Coding Mar. 14

Documentation Apr. 20

Prototype Presentation Apr. 28

Schedule

Task Duration Start Date End Date

|

Documentation |

142 days |

10/6/99 8:00 |

4/20/00 17:00 |

|

Test

Document |

58 days |

2/1/00 8:00 |

4/20/00 17:00 |

|

Linear/DSP |

120 days |

10/11/99 8:00 |

3/24/00 17:00 |

|

Web

Development Software |

40 days |

10/11/99 8:00 |

12/5/99 17:00 |

|

Digital

to Analog Converter |

38 days |

10/11/99 8:00 |

12/1/99 17:00 |

|

Analog to

Digital Converter |

38 days |

10/11/99 8:00 |

12/1/99 17:00 |

|

Programmable

Gain Amplifier |

38 days |

10/11/99 8:00 |

12/1/99 17:00 |

|

Strain

Gauge |

16 days |

10/11/99 8:00 |

11/1/99 17:00 |

|

Input/Output |

110 days |

10/11/99 8:00 |

3/10/00 17:00 |

|

Final MC

Code |

139 days |

10/11/99 8:00 |

4/20/00 17:00 |

|

MS

Project Plan |

4 days |

10/6/99 8:00 |

10/11/99 17:00 |

|

Design

Plan |

4 days |

10/6/99 8:00 |

10/11/99 17:00 |

|

Client

Satus Report |

3 days |

10/21/99 8:00 |

10/25/99 17:00 |

|

Draft

Proposal |

11 days |

11/8/99 8:00 |

11/22/99 17:00 |

|

Chip

Documentation |

19 days |

10/6/99 8:00 |

11/1/99 17:00 |

|

Final

Proposal |

1 day |

11/29/99 8:00 |

11/29/99 17:00 |

|

Proposal

Acceptance |

1 day |

12/6/99 8:00 |

12/6/99 17:00 |

|

Testing |

98 days |

11/25/99 8:00 |

4/10/00 17:00 |

|

Final

Test |

11 days |

3/27/00 8:00 |

4/10/00 17:00 |

|

Microcontroller

Test |

6 days |

3/14/00 8:00 |

3/21/00 17:00 |

|

SG

Simulation Test |

5 days |

11/25/99 8:00 |

12/1/99 17:00 |

|

Communication |

72 days |

10/11/99 8:00 |

1/18/00 17:00 |

|

Initial

Client Contact |

9 days |

10/12/99 8:00 |

10/22/99 17:00 |

|

Internal

Project Review 1 |

5 days |

10/11/99 8:00 |

10/15/99 17:00 |

|

Internal

Project Review 2 |

1 day |

1/18/00 8:00 |

1/18/00 17:00 |

|

Faculty Advisor

Meetings 1 |

1 day |

10/25/99 8:00 |

10/25/99 17:00 |

|

Faculty

Advisor Meetings 2 |

1 day |

10/27/99 8:00 |

10/27/99 17:00 |

|

Faculty

Advisor Meetings 3 |

1 day |

11/8/99 8:00 |

11/8/99 17:00 |

|

Faculty

Advisor Meetings 4 |

1 day |

11/29/99 8:00 |

11/29/99 17:00 |

|

Faculty

Advisor Meetings 5 |

1 day |

12/2/99 8:00 |

12/2/99 17:00 |

|

Communication

with client 1 |

5 days |

10/18/99 8:00 |

10/22/99 17:00 |

|

Communication

with client 2 |

1 day |

11/30/99 8:00 |

11/30/99 17:00 |

|

Hardware |

15 days |

11/22/99 8:00 |

12/10/99 17:00 |

|

Component

Selection |

15 days |

11/22/99 8:00 |

12/10/99 17:00 |

|

Software |

125 days |

10/11/99 8:00 |

3/31/00 17:00 |

|

Microcontroller

Programming |

125 days |

10/11/99 8:00 |

3/31/00 17:00 |

|

Demonstration |

1 day |

4/28/00 8:00 |

4/28/00 17:00 |

|

Design

Conference |

1 day |

4/28/00 8:00 |

4/28/00 17:00 |

|

Final

Demonstration |

1 day |

4/28/00 8:00 |

4/28/00 17:00 |

|

Presentation |

20 days |

10/11/99 8:00 |

11/5/99 17:00 |

|

Class

Presentation #1 |

1 day |

10/11/99 8:00 |

10/11/99 17:00 |

|

Class

Presentation #2 |

1 day |

11/5/99 8:00 |

11/5/99 17:00 |

|

Purchasing |

2 days |

12/10/99 8:00 |

12/13/99 17:00 |

|

Bill of

Materials/Purchased |

2 days |

12/10/99 8:00 |

12/13/99 17:00 |

|

Promotion |

23 days |

10/14/99 8:00 |

11/15/99 17:00 |

|

Web Page |

23 days |

10/14/99 8:00 |

11/15/99 17:00 |

|

Complete

Members Page |

7 days |

10/14/99 8:00 |

10/22/99 17:00 |

|

Project

Desription |

7 days |

10/14/99 8:00 |

10/22/99 17:00 |

|

Project

Schedule |

12 days |

10/21/99 8:00 |

11/5/99 17:00 |

|

Post

Documents |

12 days |

10/21/99 8:00 |

11/5/99 17:00 |

|

Advertise

Web Page |

12 days |

10/29/99 8:00 |

11/15/99 17:00 |

|

Project

Control |

11 days |

11/22/99 8:00 |

12/6/99 17:00 |

|

Cost

Analysis |

8 days |

11/22/99 8:00 |

12/1/99 17:00 |

|

Proposal

Submission |

1 day |

11/29/99 8:00 |

11/29/99 17:00 |

|

Proposal

Approval |

1 day |

12/6/99 8:00 |

12/6/99 17:00 |

|

Research |

37 days |

10/11/99 8:00 |

11/30/99 17:00 |

|

I/O

Interface |

26 days |

10/11/99 8:00 |

11/15/99 17:00 |

|

Linear/DSP |

37 days |

10/11/99 8:00 |

11/30/99 17:00 |

|

Programmable

Gain Amplifier |

26 days |

10/11/99 8:00 |

11/15/99 17:00 |

|

Digital

to Analog Converter |

26 days |

10/11/99 8:00 |

11/15/99 17:00 |

|

Analog to

Digital Converter |

26 days |

10/11/99 8:00 |

11/15/99 17:00 |

|

Microcontroller |

16 days |

10/11/99 8:00 |

11/1/99 17:00 |

|

Travel |

1 day |

11/12/99 8:00 |

11/12/99 17:00 |

|

Tucson

trip to Dataforth |

1 day |

11/12/99 8:00 |

11/12/99 17:00 |

|

|

|

|

|

Design

Section

Design Summary

Analog Design

The analog portion of the system

consists of a resistor network for simulation of a strain gauge, and a differential

amplifier with a set gain of 100, for adjusting the output of the strain gauge

into a more workable range (See Appendix A for schematics and simulation

data). Two voltage divider circuits

simulate the strain gauge; both powered by the same supply voltage adjustable

from 1 to 10 volts. The outputs of the

voltage divider circuits are independent of each other.

The first division provides a reference voltage

feeding into the negative terminal of the amplifier. The other voltage divider output is adjusted, through a digital

to analog converter (DAC), to match as closely as possible the voltage at the

positive input of the amplifier to the reference voltage at the negative input

of the amplifier.

By adjusting the inputs of the amplifier to match we

eliminate the difference between the terminals and obtain a common mode input

scenario, therefore producing no output signal from the amplifier. After the DAC has zeroed the bridge, we

adjust the potentiometer in the voltage divider circuit, which in turn changes

the reference voltage at the negative input of the amplifier. The difference between the two terminals

will be varied from 12.8 mV to 128 mV.

The adjusted difference in voltage simulates a strain being placed on a

gauge after it has been calibrated or zeroed.

Digital Design

The digital section of the system consists of 4

distinct parts: a Microcontroller, an Analog to Digital Converter (ADC), a

Digital to Analog Converter (DAC) and a Programmable Gain Amplifier (PGA).

The microcontroller sets the voltage

level for the op-amp in the analog section through a DAC, which in turn zeroes

the system. After receiving the signal from the strain gauge, the PGA sets the

gain of the amplifier to x1, x2, x4, or x8.

The signal is then sent to an ADC, which in turn feeds the converted

data back to the microcontroller for further analysis. The microcontroller receives, through a

serial communication port, the data for the gain stage, the ADC, and the DAC. It sets the gain of the PGA, calibrates the system

via the DAC in the control loop, and tells the ADC whether a digital or analog

signal is required.

Schematics, Diagrams and Drawings

A Block Diagram of the overall

system is shown in Figure 1.2, below.

The Strain Gauge Simulator and Differential Amplifier are shown

configured together in the schematic located in Appendix A, page A-8, creating

the analog portion of the design.

Figure 1.2, Block Diagram of the System

Figure 1.2, Block Diagram of the System

Analysis and Simulation

PSpice simulations were run to

verify the functionality of the differential amplifier and the strain gauge

simulator both individually and collectively.

Appendix A, pages A-1 – A-4, show the schematic and simulation results

from the strain gauge simulator, while pages A-5 – A-7, in Appendix A, show the

schematic and results from the differential amplifier simulation. Also found in Appendix A, on pages A-9 –

A-13, are the results of the combined system of the strain gauge simulator and

the differential amplifier. The results

clearly state that the circuit should function as anticipated.

An actual simulation was done in

addition to verify the functionality of the circuit and agreed with the

computer simulation results. The

experimental circuit used 5% tolerant resistors and a 25-ohm potentiometer but

provided accurate enough results to confirm proper design and operation of the

analog portion of the design.

Tradeoff and Design Decisions

Initially, there was indecision over

using parallel versus serial mode interactions between the microcontroller and

the ADC, DAC and the PGA. However, after learning that parallel interfacing was

possible by using two 8-bit I/O ports from the microcontroller, the idea of

using serial interface was discarded.

The use of 16 bit digital parts was decided upon in

order to meet the design specification of 0.1% accuracy. 16 bits provide a safe margin for noise and

bit swamping while maintaining accurate results. It was also decided that a 100-ohm potentiometer would be used in

order to simulate a greater input voltage range. This extended range allows for worst-case testing to be

performed.

Another issue is the operating speed

of the microcontroller. In order to keep the noise to a minimum, the

microcontroller needs to be run at a speed as low as possible. However, care

needs to be taken that the microcontroller is not run at a speed below what is

necessary to effectively read the required bandwidth of the system. Although

this is a consideration, it is not of primary concern. Clock speed noise is minimal in comparison

to other noise issues within the system.

Ground planes will be used to

further reduce noise by reducing the size of induced current loops. However,

the primary source of noise in our system will be the proximity of the analog

section to the digital section. This problem will be solved by physically

separating the two sections and connecting them at one, and only one, point for

cross-communication. Furthermore, the

reduction of noise in the system will continue to be of primary concern for

design decisions.

Parts Description

All resistors are rated for ¼ Watt

and have tolerances of 1%. The

potentiometer has a range of up to 100 Ohms.

The operational amplifier will be a high performance LM741. In order to reduce noise, Vectorbord containing

a ground plane will be used to mount the components. A mini Bud Box will also be used to enclose the circuit,

therefore protecting it from elements as well as providing further shielding

from noise.

The

microcontroller used will be the EPROM-based PIC17C756. The ADC will be16-bit integrating type for

better accuracy. The DAC will also be 16-bit.

A full description of the parts used may be found in Appendix B.

Budget Section

Part Number Description Qty Price Vendor

100XBX-ND 100 Ohm 1/4W 1% Axial 10 $1.08 Digi-Key

Metal Film Resistor

2.00KXBX-ND 2000 Ohm 1/4W 1% Axial 5 $0.54 Digi-Key

Metal Film Resistor

10.0KXBX-ND 10000 Ohm 1/4W 1% Axial 5 $0.54 Digi-Key

Metal Film Resistor

LM741CN-ND High Performance Operational 1 $0.56 Digi-Key Amplifier

V1009-ND P Bord/ 8.5 X 17”/ Copper Clad 1 $23.81

Digi-Key 1

side

V1056-ND Pad Cutter Tool with Handle 1 $20.90

Digi-Key

V1069-ND Microklip T42-1/C terminal 2 $10.64

Digi-Key

100 Count Package

V1101-ND Insertion Tool for Microklip 1 $18.10

Digi-Key

91F709 Minibox Housing 1 $22.82 Newark Electronics

318230 6ft serial db25m/db25f 1 $4.99 Insight

ADS7805P-ND IC 16 Bit A/D 28-DIP.3” 1 $31.90 Digi-Key

PGA203KP-ND IC Prog Gain Instr Amp 14 DIP 1 $11.02 Digi-Key

DAC712P-ND IC 16 Bit D/A Conv. 28 DIP.3’ 1 $18.72 Digi-Key

The estimated cost of

the prototype unit is $165.62. The

estimated cost of a production unit, excluding the printed circuit board and

housing, is approximately $30. Rob Cote

at Northern Arizona University will supply a computer for coding and

development of the mircocontroller, at an estimated cost of $500 for the

computer system. We will attempt to

obtain a microcontroller development package donation through Microchip's

University Program-Systems. If we are

unable to obtain these tools free of cost, Dataforth will purchase and provide

the necessary tools. We will provide a

bill of materials to Dataforth for the other components of the system and

Dataforth will purchase and provide the necessary materials by February 1,

2000. This is the payment arrangement

discussed and agreed upon.

Acceptance Document

This agreement sets forth the terms and

conditions for your use of this design.

We

agree that YOU shall be the patent proprietor in all patentable inventions of

every kind and description created or developed with regard to this design.

DISCLAIMER

OF WARRANTY

You

agree that your use of any part of this design and our services, and other data

and information is provided on an “AS IS” BASIS. EXCEPT AS EXPRESSLY SET FORTH

HEREIN, ALL CONTENT, SOFTWARE, HARDWARE, FUNCTIONS, SERVICES, MATERIALS AND

INFORMATION MADE AVAILABLE OR OTHERWISE PROVIDED, IS PROVIDED AS IS, WITHOUT

WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED. WE EXPRESSLY DISCLAIM ANY

WARRANTIES OF ANY KIND, INCLUDING, BUT NOT LIMITED TO, WARRANTIES OF TITLE OR

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR USE OR PURPOSE,

TITLE, COMPATABILITY, SECURITY, ACCURACY, AVAILABILITY, DESIGN, CAPABILITY,

SUFFICIENCY, COMPLETENESS, OR NON-INFRINGEMENT. TO THE FULLEST EXTENT

PERMISSIBLE BY LAW, WE MAKE NO WARRANTIES AND SHALL NOT BE LIABLE FOR THE USE

OF THE DESIGN UNDER ANY CIRCUMSTANCES, INCLUDING BUT NOT LIMITED TO NEGLIGENCE

BY WE. DO NOT WARRANT THAT THE SOFTWARE, HARDWARE, FUNCTIONS, SERVICES,

MATERIALS AND INFORMATION MADE AVAILABLE OR OTHERWISE PROVIDED, CONTAINED IN

THE SITE OR SERVICES WILL BE UNINTERRUPTED OR ERROR-FREE, THAT DEFECTS WILL BE

CORRECTED, THAT THE SITE OR SERVICES WILL MEET ANY PARTICULAR CRITERIA OF

PERFORMANCE OR QUALITY, OR THAT THE SITE, INCLUDING FORUMS OR THE SERVER(S) ON

WHICH THE SITE IS OPERATED, ARE FREE OF VIRUSES OR OTHER HARMFUL COMPONENTS.

Neither WE or anyone else involved in creating, producing or delivering

services shall be liable for any direct, indirect, incidental, special or

consequential damages arising out of the use or inability to use this design.

LIMITATION

OF LIABILITY

USE OF THE DESIGN IS AT YOUR OWN RISK. YOU ASSUME FULL RESPONSIBILITY AND RISK OF LOSS RESULTING FROM YOUR DOWNLOADING AND/OR USE OF FILES, INFORMATION, COMMUNICATIONS, CONTENT, OR OTHER MATERIAL (INCLUDING WITHOUT LIMITATION SOFTWARE) ACCESSED THROUGH OR OBTAINED BY MEANS OF THE SITE. UNDER NO CIRCUMSTANCES SHALL WE BE LIABLE FOR ANY INDIRECT, PUNITIVE, SPECIAL, OR CONSEQUENTIAL DAMAGES THAT ARE DIRECTLY OR INDIRECTLY RELATED TO THE USE OF, OR THE INABILITY TO USE, THE SITE OR SERVICES, EVEN IF WE HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. THE TOTAL LIABILITY OF US HEREUNDER IS LIMITED TO THE AMOUNT, IF ANY, ACTUALLY PAID BY YOU TO US, WHICH IS ZERO. YOU HEREBY RELEASE US FROM ANY AND ALL OBLIGATIONS, LIABILITIES AND CLAIMS.

WITNESS

my hand and seal this day of , 19 .

ACCEPTED

FOR US

By:

Date:

Name Greg Sitrick

By:

Date:

Name Vishal Golia

By:

Date:

Name Scott Hancock

By:

Date:

Name Donnie

Yazzie

ACCEPTED

FOR YOU

By:

Date:

Name Lee

Payne